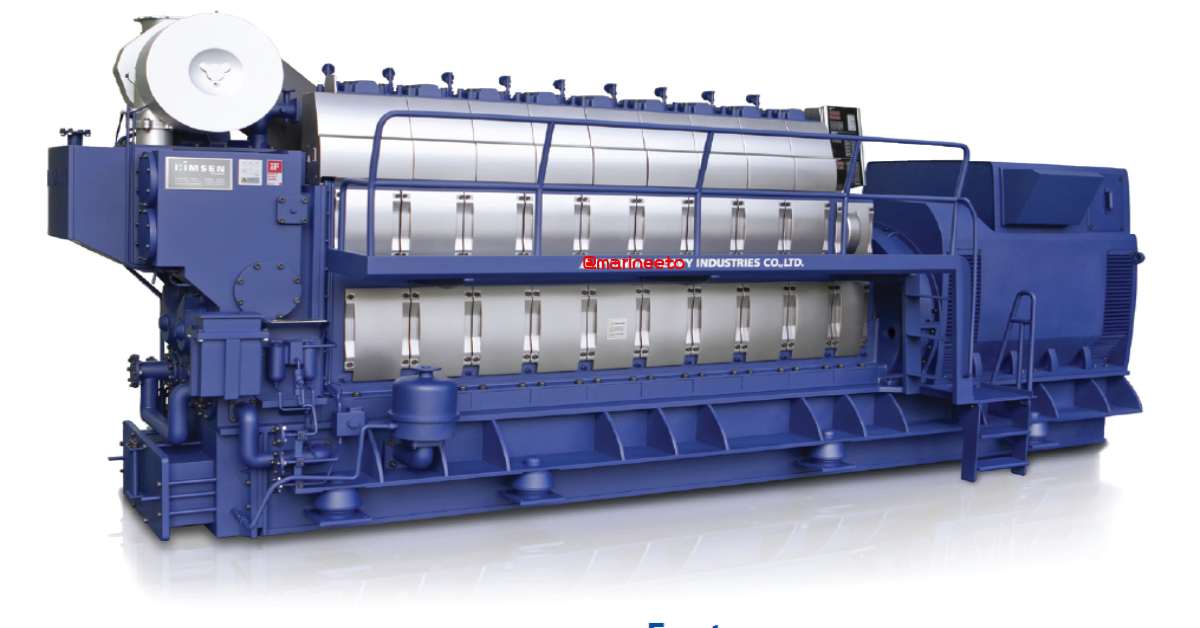

MARINE ALTERNATOR MAINTENANCE GUIDE

To ensure safe operation & uninterrupted power onboard, routine maintenance on the alternator is must.

Before starting any maintenance work on the alternator, make sure all necessary safety precautions should be taken and the alternator should be shut and locked down.

Here is a list of marine alternator maintenance guide for ETO.

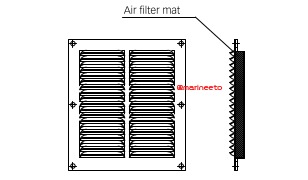

WINDING AIR FILTERS

Inspect the condition of air filters on the alternator every month so that there is an obstruction for the flow of air through windings, The filter may be choked due to dust & carbon deposit on it so its good to replace the filter.

Some alternators have a temperature transmitter embedded so if there is a rise in winding temperature then an alarm is triggered.

In some cases cooling of winding is carried out by cooling fresh water & heat exchanger, separate safety alarm feature is installed in case of water leak.

Improve the quality & thickness of the Air Filter if you see dust, oil film in the inner body windings of the alternator.

Inspect and clean the ship generator rotor and stator windings by removing dust with a dry lint-free cloth. Low pressure, dry compressed air may be used to desludging heavier dirt but be careful not to drive the dirt deeper into the windings.

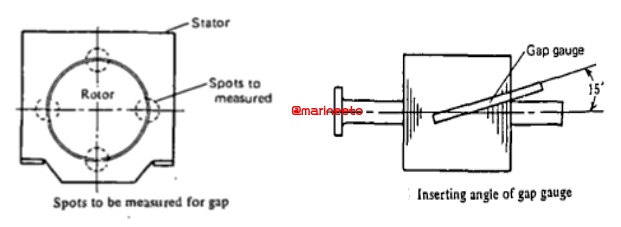

AIR GAP MEASUREMENTS

Air Gap measurements can be carried out whenever you are doing alternator air filter routines. The typical value of airgap between rotor & stator must be 2mm to 3mm (preferably 300mm to 500mm feeler gauge is used). Air Gap must be measured using a plastic feeler gauge, Do not use a metal feeler gauge it can damage the winding insulation slightly.

More the Airgap, Abnormal vibration, wearing of bearing, decrease in power factor but minimized armature reaction.

Lesser the Airgap, Noise increases, power factor increases & increased core losses.

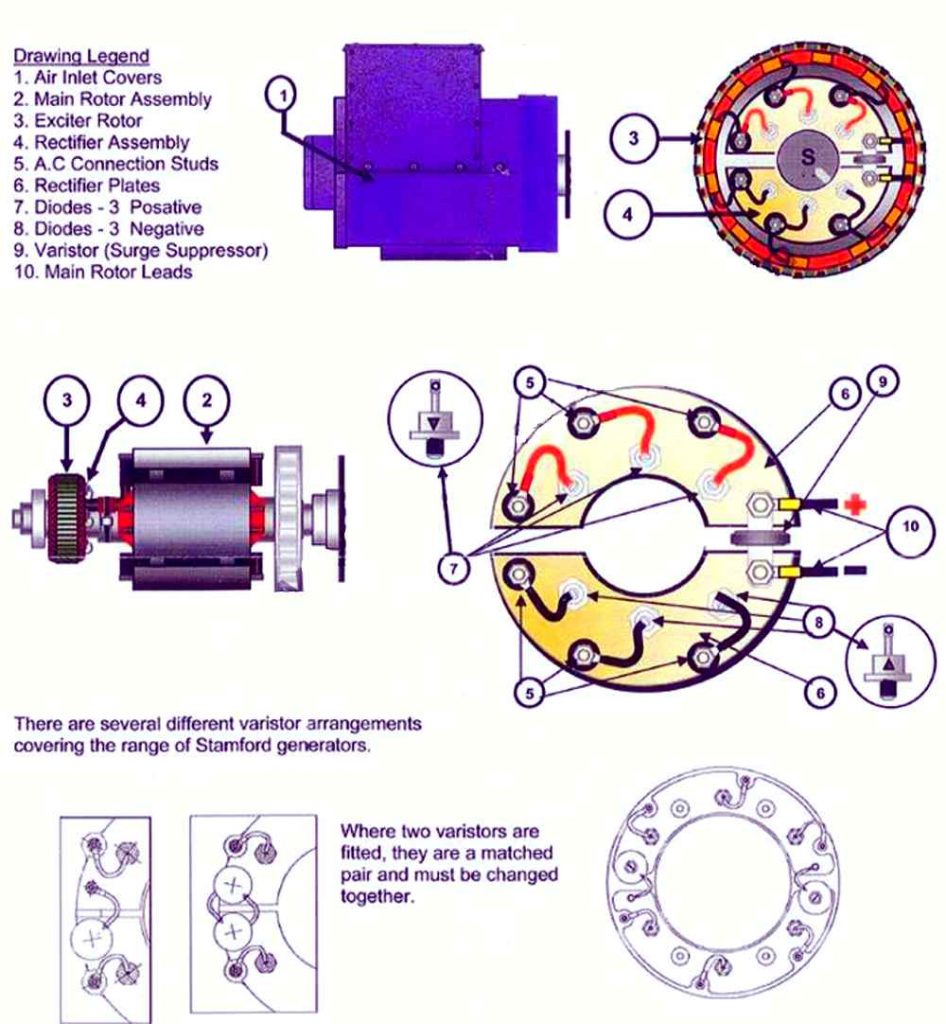

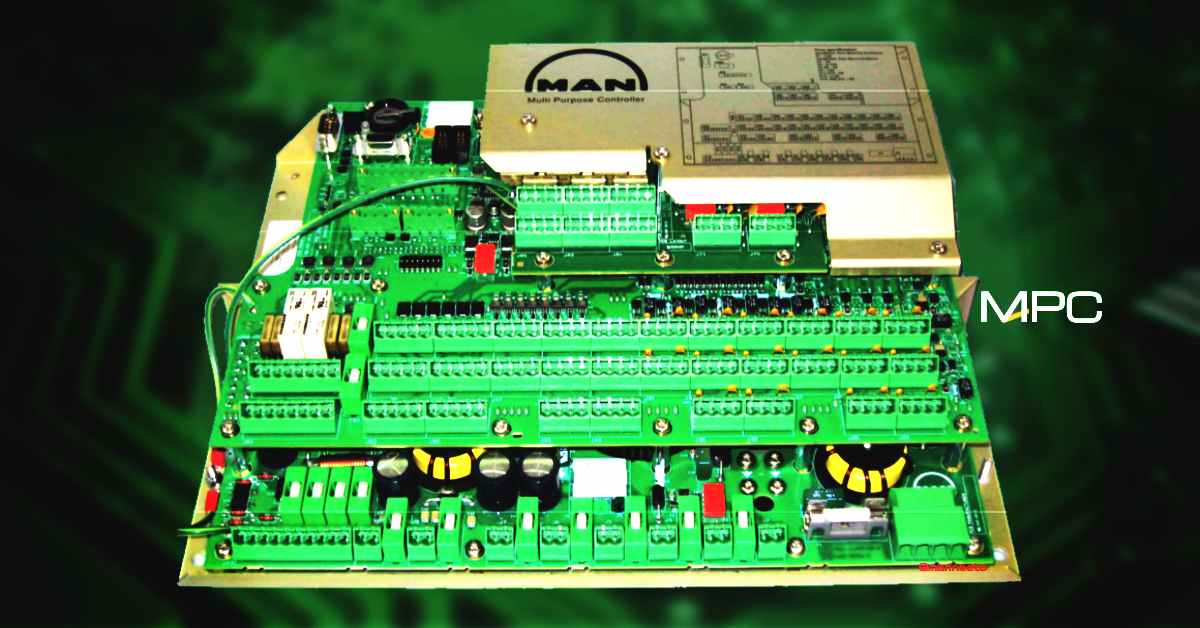

ROTATING DIODE CHECKS

If Rotating Diode/Silicon Module fails, there is an abnormal raise in temperature in exciter windings, unstable voltage.

| DIODE MODE | HEALTHY DIODE | FAULTY DIODE |

|---|---|---|

| FORWARD BIAS | 10Ω | 0Ω or more than 10Ω |

| REVERSE BIAS | 100KΩ | Greater or Less than 100KΩ |

Some Alternator healthy Rotating Diode gives a reading of 10 to 100Ω when forward biased. Similarly, for faulty diode, 0Ω (short), MΩ, or more (open) when forward or reverse bias.

MEGGAR TEST

Megger test has to be carried out to ensure the insulation resistance of stator & rotor between phase to the body is within acceptable limits. It must be the least of 1MΩ always its good to have a higher insulation resistance value.

When lower insulation resistance is identified in the stator or rotor, clean

them according to the following procedure.

Also, when no insulation resistance returns to normal even if the following

work is conducted, contact the specialist or our company.

Isolate AVR & Rotating diode while performing Meggar on Alternator.

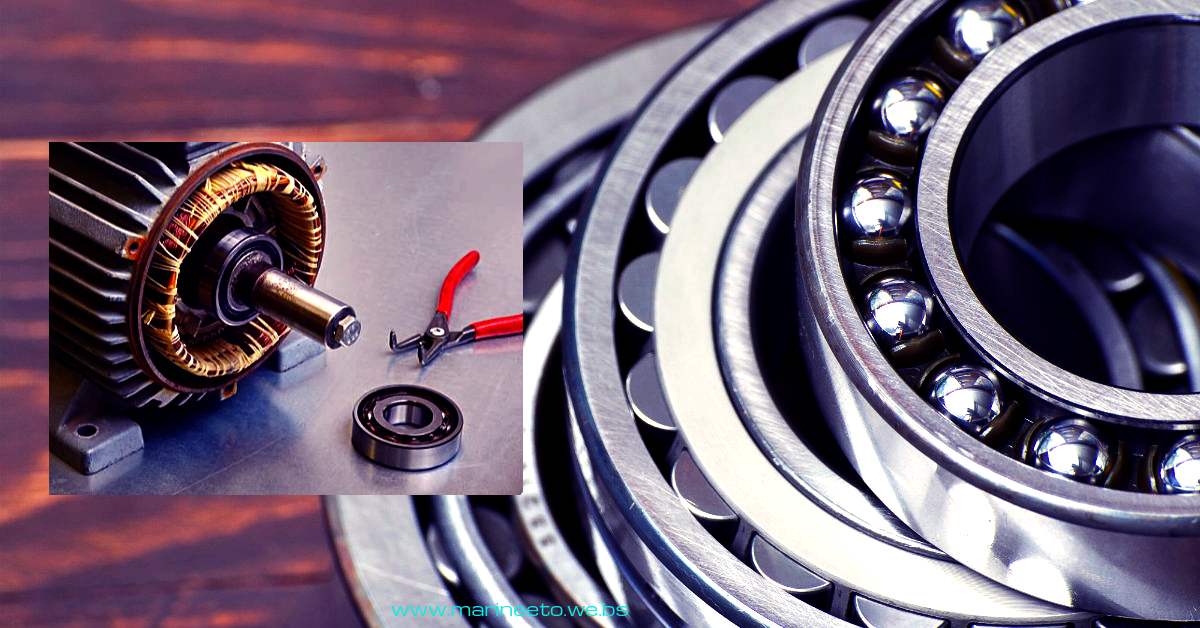

BEARING OIL RENEWAL

For some Alternator, Bearing oil must be renewed after certain running hours if self-lubricated because after a certain time duration bearing loses lubricating property. Lubrication reduces friction and abrasion, reduces heat, and extend the life of the bearing.

Its good to check oil level & colour during daily routine.

ADDITIONAL CHECKS

- Clean inside the alternator windings with approved non-flammable solvents, to improve insulation & remove dust.

- Check the value of surge suppressor resistor (varistor), typical value must be around 100MΩ. A good surge suppressor will have very high resistance.

- Check for abnormal temperature & vibration.

- Check for all wiring to the alternator, tightness of the terminal connection & condition of cable insulation.

- Also, check space heater is operational or not.

REFERENCES

- Nishishiba Electric http://www.nishishiba.co.jp/

- Hyundai Electric http://www.hyundai-electric.com

ALSO READ ALTERNATOR QnA

Have content to share? write us to mail@marineeto.we.bs

LIKE POST? PLEASE SHARE

Thanks a lot for this knowledge sharing, It’s so useful.

Genset Maintenance

which type of cables used from alternator to msb

XLPE

Very helpful for exam preperations

yes

Its a good point that you have mentioned that one needs to use plastic feeler gauges for air gap measurements. But have you ever taken these air gaps ever on board? Its a great thing if you have a practical experience of the same. In my almost 25 years at sea (15 years as CE on DP vessels, I have not seen any plastic feeler gauges. You have a good informative blog, BTW.