DRY DOCK ELECTRICAL JOBS EVERY ETO MUST KNOW

Here is a list of Electrical jobs that must be planned in the Dry dock by the Electrical Superintendent/ ETO, for better conditioning & monitoring of electrical equipments in the ship.

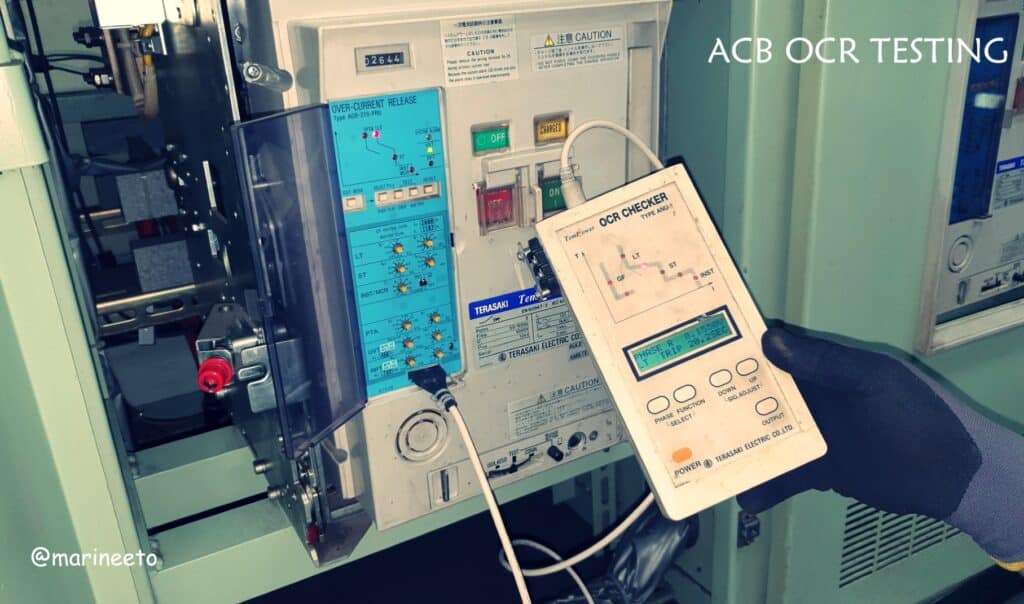

1.ACB OVERHAUL & TESTING

Breakers must be tested for their safe operation. Inspection must be carried out on arc chutes, moving & fixed contacts, motors & spring mechanism, etc. Operation test on OLR using calibrated testing equipment, time taken for STD (Short Time Delay) trip, LTD (Long Time Delay) trip & Instantaneous trip must be recorded & compared with maker reference value.

2.MAIN & EMERGENCY SWITCHBOARD MAINTENANCE

This also includes bus bar inspection (thermal imaging using IR camera), tightness & overheating checks, testing of safety devices, calibration of earth meters, synchroscopes, and power meters. Cleaning is also to be carried out by shore personnel (strict safety precautions must be taken).

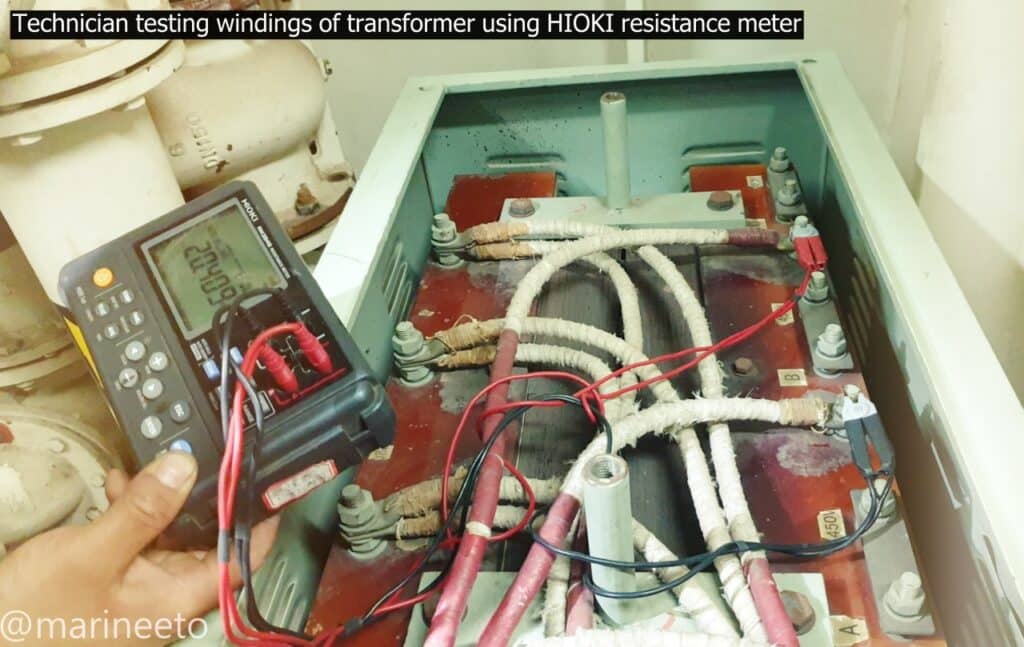

3.TRANSFORMER MAINTENANCE

It is better to undergo complete inspection & maintenance which includes inspection & cleaning of windings, space heaters & cooling medium (if applicable), terminal tightness, arc flash or sign of overheating, Insulation resistance & winding resistance test.

4.ALTERNATOR MAINTENANCE

Complete maker recommended inspection & operation test must be carried out. Visual inspection on windings, IR test on windings, condition of space heaters, dust accumulation must be cleaned. If heat exchangers are water cooled, check for the signs of leakages in piping & heat exchangers. Air gap measurements must be carried out. Terminal tightness & physical conditions at terminal must be noticed. Recommended testing of all the safety devices to ensure safe operation.

read also: alternator maintenance guide

5.CALIBRATION OF MEASURING INSTRUMENTS

In machinery plants, Level gauge instruments like sensor, DP transmitter, detectors must be calibrated for accurate & reliable operation. Also recommended calibrating all measuring tools like temperature calibrator, pressure calibrator, multimeter, etc.

All gas detection system, ows, boiler plant, cargo & tank level gauging system instruments must be calibrated for accuracy.

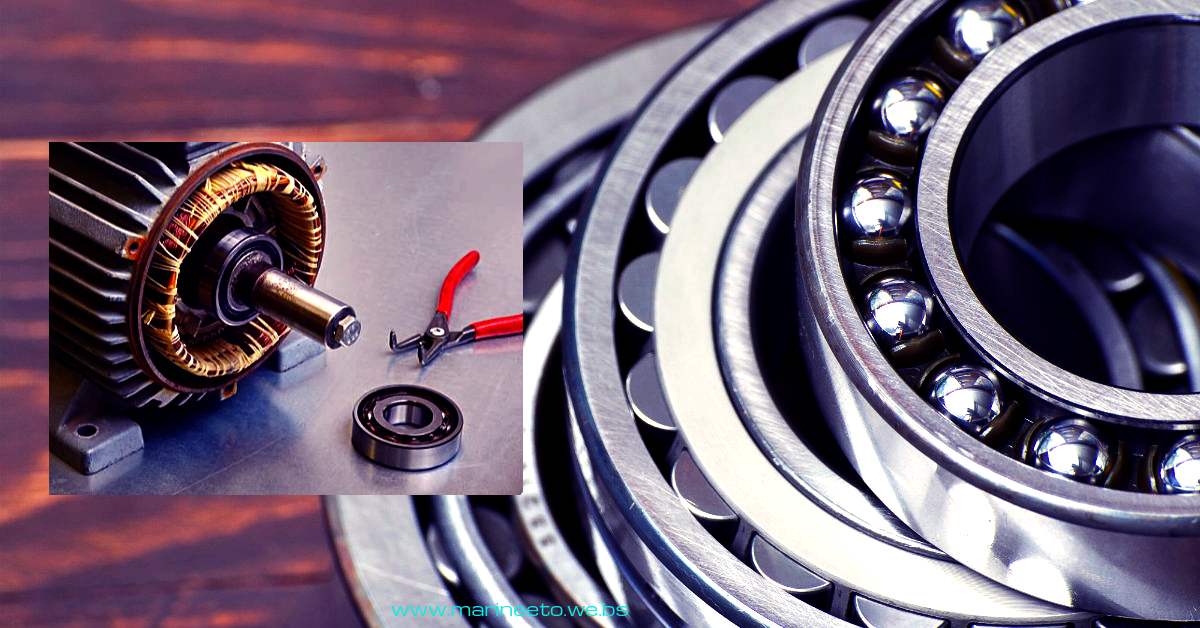

6.MOTOR OVERHAUL

List must be prepared for the motor which cannot be put out of service during vessel operation like cooling pump motors, lubrication pump motor, control air compressor motor, etc. Also, the motor which are huge & heavier which requires more man power must be overhauled in dry dock. Perform a vibration test using vibration monitor or sound scope to analyze the condition of the motor. Bearings are recommended to replace after 24 months to avoid breakdown, if engaged in continuous operation.

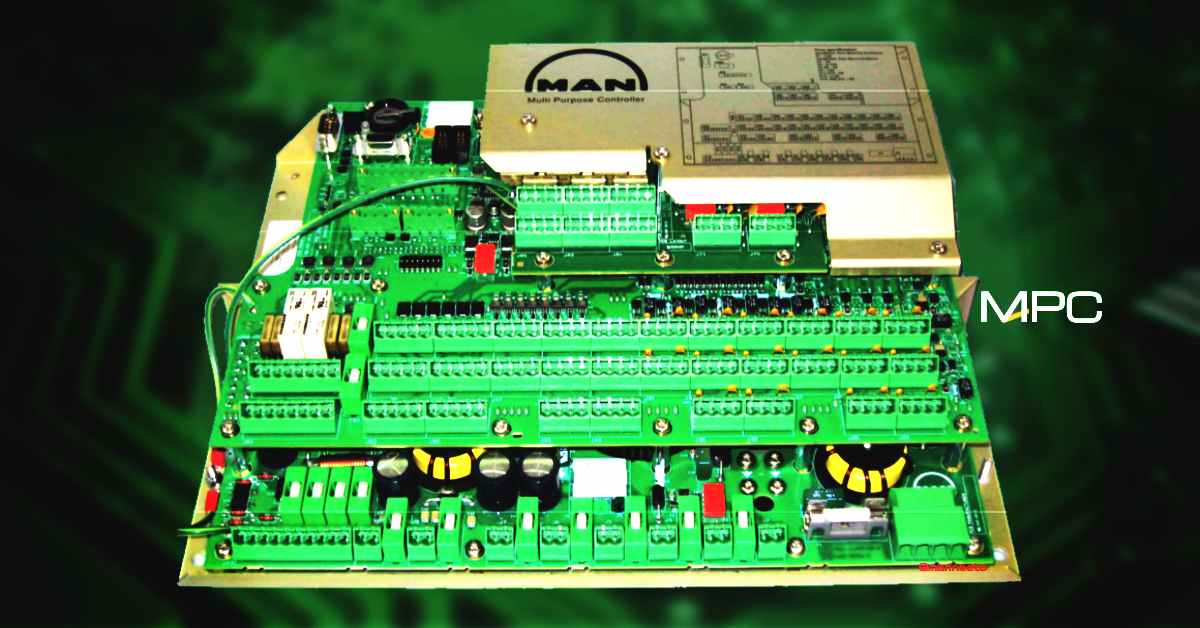

7.EQUIPMENT UPGRADE

Most of outdated equipment software & hardware must be upgraded to latest version because after years of operation equipments more likely give errors & some spares may go obsolete, supplier may find difficult to get similar or alternative spare in the future. At top most priority, navigation equipment software & hardware must be upgraded to avoid technical issues in the future.

8.CATHODIC PROTECTION MAINTENANCE

Most of the ship is equipped with cathodic protection (ICCP) so anodes on hull & reference cell, condition of dielectric must be inspected, replace cells (if required). Overall operation test must be simulated if cathodic protection can work in automatic mode.

9.SHORE POWER

Know procedure for changing over power from generators to shore power. Make a list of critical equipment which must be powered on always. Normally there are shore electricians while connecting & disconnecting shore power cables, Also they check phase sequence while connecting.

In some cases, bus-tie never close automatically when emergency generator set in manual mode, in such cases bus-tie is closed manually.

VIDEO

CONCLUSION

Planned dry dock jobs are subjected to technical manager approval, jobs may get approved or cancelled based on several factors like time, budget, etc. Dry docks are hectic cause many number of jobs have to be executed!. Make sure you follow all the required safety procedures before starting any job. The good perks for seaman in dry dock are can go ashore after work & enjoy the life during dry dock.

Anything missing? Please comment.