TYPES OF TEMPERATURE SENSOR USED ON BOARD SHIP

The temperature sensor is sometimes known as a transducer that converts heat energy to proportional electrical signals. The temperature sensor is an important instrument used onboard to measure process value and to ensure that plant is working satisfactorily.

In this article, we will discuss the various type of temperature sensors used onboard ship and their application.

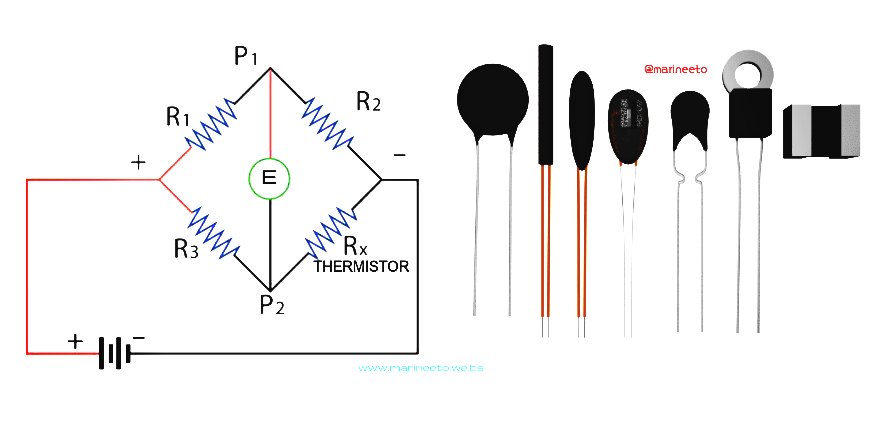

THERMISTOR

A Thermistor is a sensitive transducer whose electrical properties like resistance vary as per temperature in other words its Thermally Controlled Resistor. A thermistor is a sensitive semiconductor metal oxides whose resistance increases or decreases for increase or decrease in temperature.

Based on increase & decrease in resistance thermistor is classified as,

- PTC or Positive Temperature Coefficient Thermistors are those whose resistance increases with an increase in temperature.

- NTC or Negative Temperature Coefficient Thermistor are those whose resistance decreases with an increase in temperature.

For Temperature Measurements Thermistor is placed in the Wheatstone bridge network under balanced conditions there is no flow of current in the midpoint of the network i.e, P1 and P2 since the potential drop is the same at two ends. When the temperature further raises/lowers there is a change in resistance the bridge unbalanced there is a voltage drop across P1 and P2 this voltage further amplified converted to digital data using ADC (analog-digital converter).

Thermistors are used on board ship in Motor Winding Temperature measurements. In the fire alarm system, it is used in some Heat detectors.

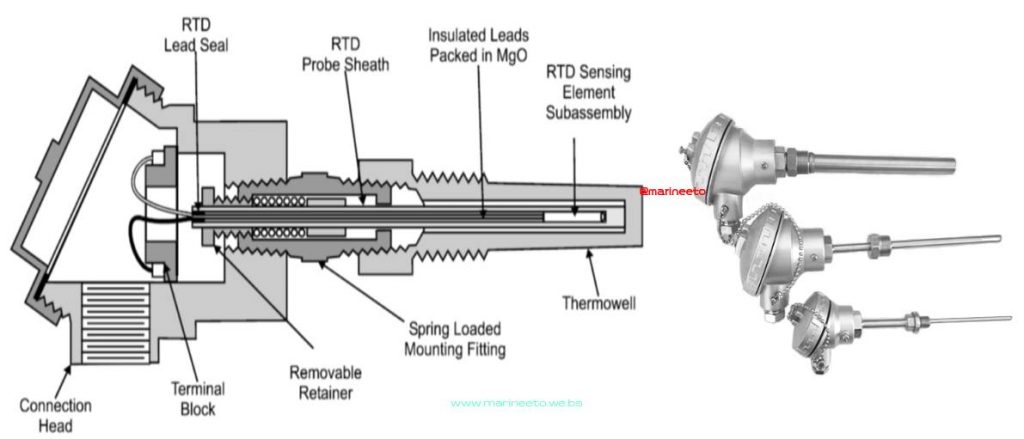

RTD (RESISTANCE TEMPERATURE DETECTOR)

RTD is similar to a thermistor. Instead of semiconductor, metallic resistance wire is used as a sensing element. The sensing element is small turns of resistance wire forming coil is placed inside the ceramic enclosure. The resistance wire is free to expand and contract as temperature changes, minimizing error caused by a mechanical strain. The air gap is filled with Magnesium oxide powder which provides better heat transfer from ceramic(Thermowell) to the coil.

The commonly used component as resistance wire(sensing element) are Platinum(Pt), Nickel(Ni) & Copper(Cu).

Platinum is highly used because it has the highest temperature range, Stability, and Corrosion resistive. Popularly used Platinum RTD are Pt100, Pt1000. The name Pt100 is because at 0°C resistance is 100 Ohms.

Pt100 is commonly used temperature sensor onboard ship. Almost all machineries like Main Engine, Generators, Tank Monitoring System, etc use Pt100 sensor.

The sensing resistance of the element used in a Pt100 sensor increases with an increase in temperature, see a chart that describes temperature versus resistance relation.

| TEMPERATURE (°C) | RESISTANCE (Ω) | TEMPERATURE (°C) | RESISTANCE (Ω) |

|---|---|---|---|

| 0 | 100 | 130 | 149.83 |

| 10 | 103.9 | 140 | 153.58 |

| 20 | 107.79 | 150 | 157.33 |

| 30 | 111.67 | 160 | 161.05 |

| 40 | 115.54 | 170 | 164.77 |

| 50 | 119.4 | 180 | 168.48 |

| 60 | 123.24 | 190 | 172.17 |

| 70 | 127.08 | 200 | 175.86 |

| 80 | 130.9 | 300 | 212.05 |

| 90 | 134.71 | 400 | 247.09 |

| 100 | 138.51 | 500 | 280.97 |

| 110 | 142.29 | 600 | 313.70 |

| 120 | 146.07 | 700 | 345.28 |

From the chart, it is clear that for every 10 °C rise in temperature the resistance increases approximately 3.6 to 4 Ohms. Also, this table helps in troubleshooting sensor.

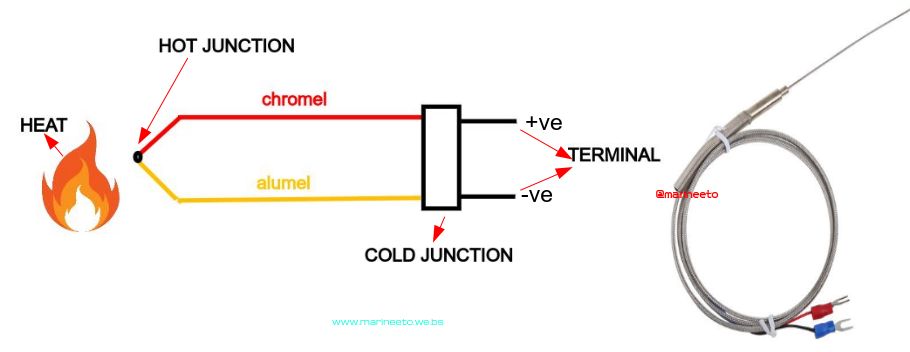

THERMOCOUPLE

The thermocouple is a two-wire measuring device made up of two dissimilar metals that are used together forming junction which is a welded spot this spot is known as Hot Junction. Hot junction is a heat-sensing end. The other end at which small EMF is generated is known as the cold junction which is connected to terminals. The generated EMF is DC and the +ve and -ve terminal depends on the type of element used. Refer to the figure for better understanding.

The thermocouple principle mainly depends on the three effects namely Seebeck, Peltier, and Thompson. The amount of EMF generated is very small about millivolt(mV).

Thermocouples are classified into different types namely Type-K, Type-J, Type-T, Type-E, Type-N, Type-S, Type-R, and Type-B. See below chart for more information.

| TYPE | SENSITIVITY | RANGE | COMPOSITION |

|---|---|---|---|

| K | 41 µV/°C | −200 °C to +1350 °C | (+ve terminal) Chromel=(90% Nickel, 10% Chromium) (-ve terminal) Alumel=(95% Nickel, 2% Aluminum, 2% Manganese, and 1% Silicon) |

| J | 50 µV/°C | −40 °C to +750 °C | (+ve terminal) Iron (-ve terminal) Constantan=(55% Copper, 45% Nickel) |

| T | 43 µV/°C | −200 °C to +350 °C | (+ve terminal) Copper (-ve terminal) Constantan=(55% copper and 45% nickel) |

| E | 68 µV/°C | −50 °C to +740 °C | (+ve terminal) Chromel (-ve terminal) Constantan=(55% copper and 45% nickel) |

| N | 39 µV/°C | −270 °C to +1300 °C | (+ve terminal) Nicrosil=(Nickel alloy containing 14.4% Chromium, 1.4% Silicon, and 0.1% Magnesium) (-ve terminal) Nisil=( Nickel 95.5% and Silicon 4.4% Magnesium 0.1%) |

| S | 12 µV/°C | +980 °C to +1450 °C | (+ve terminal) 90% Platinum 10% Rhodium (-ve terminal) Platinum |

| R | 14 µV/°C | 0 °C to +1600 °C | (+ve terminal) 87% Platinum 13% Rhodium (-ve terminal) Platinum |

| B | 10 µV/°C | 0 °C to +1800 °C. | (+ve terminal) 70% Platinum 30% Rhodium (-ve terminal) 94% Platinum 6% Rhodium |

The thermocouple is used in High-temperature measurement, Equipment like Incinerator, Boiler, etc.

HOW TO CHECK THERMISTOR?

Using DMM(Digital Multi Meter), Measure the resistance in order to know its a PTC or NTC, put Thermistor in Ice water or Heat surface slightly increase or decrease in temperature to know the type of thermistor. At room temperature, the NTC thermistor value will be within 15KΩ for PTC resistance is very small, (2-250 ohms) but most of the PTC sensor less than 1KΩ at room temperature. Check resistance v/s temperature chart in maker manual compare readings. Replace thermistor if faulty.

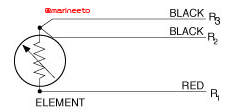

HOW TO CHECK Pt100?

Its easy to check Pt100 sensor, for two wire sensor measure the resistance and verify resistance with table given above. For healthy sensor the readings will match approximately else the sensor is faulty.

For 3-wire sensor terminal, R1 and R2 are sensing element, and terminals R2 and R3 are compensating resistor (To compensate for lead wire resistance, 3 wire RTDs have a third wire that provides a measurement of the resistance of the lead wire and subtracts this resistance from the read value ). The procedure is similar to a 2-wire sensor, actual resistance value found by subtracting read value with compensation value i.e, (R1 & R2)-(R2 & R3).

HOW TO CHECK THERMOCOUPLE?

The first step, Check continuity because most of the cases thermocouple hot junction gets open.

The Second step, Set DMM(Digital Multimeter) in mV or lowest possible DC voltage range and measure mV. Put the thermocouple in temperature calibrator and increase the temperature slowly note down the readings of mV and compare the sensitivity with the table given above depending upon the type of thermocouple. For Example, K-type thermocouple voltage raises 0.04mV per °C.

If test fails after following above two steps then replace sensor.

REFERENCES

- ELPROCUS www.elprocus.com

- Omega www.omega.com

- Vishay www.vishay.com/

LIKE POST? PLEASE SHARE

good

thank you

Thank you .

Very good information, Thank you very much

Informative post!